The evolution of technology has brought about remarkable changes across various industries, and one such innovation is 3D printing. This groundbreaking technology is revolutionizing manufacturing and personal creativity in ways that were once deemed unimaginable. With its ability to create three-dimensional objects from digital designs, 3D printing is reshaping the way we produce everything from industrial machinery to household items.

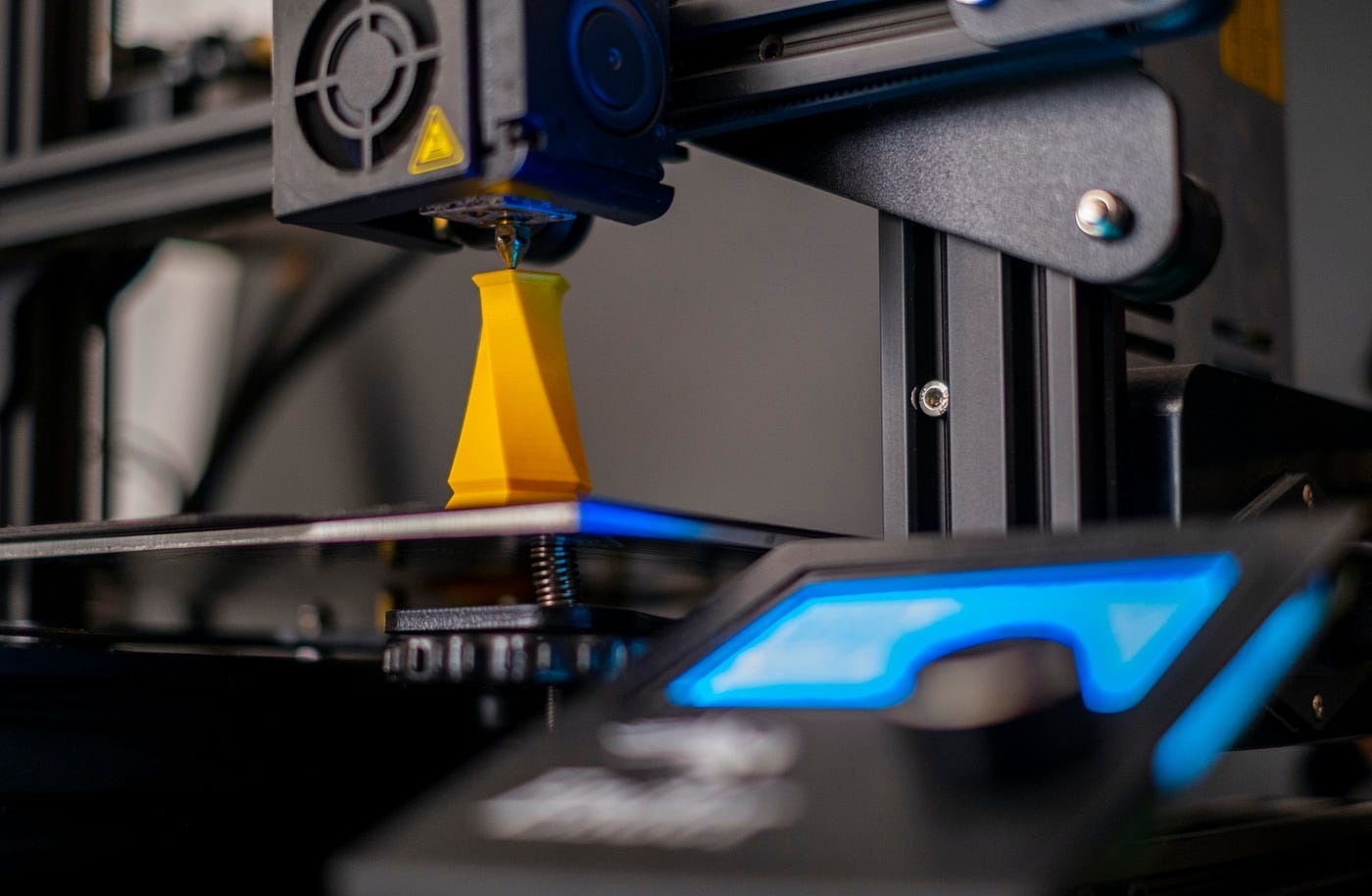

At its core, 3D printing, also known as additive manufacturing, involves layering materials to create a physical object based on a digital model. This process eliminates the need for traditional manufacturing methods, such as machining or molding, which can be time-consuming and costly. Instead, 3D printers build objects layer by layer, using materials like plastic, metal, or even food ingredients, depending on the desired outcome.

One of the most significant advantages of 3D printing is its ability to produce highly intricate and customized designs. Traditional manufacturing techniques often struggle to create complex shapes and geometries, but 3D printing effortlessly handles these challenges. This enables manufacturers to create unique products that meet specific requirements, whether it’s a lightweight aerospace component or a personalized medical implant.

Moreover, 3D printing empowers individuals to unleash their creativity and bring their ideas to life. With a 3D printer and some design software, anyone can become a maker, capable of producing their own creations. Whether it’s crafting jewelry, developing prototypes, or building intricate models, 3D printing offers endless possibilities for personal expression and entrepreneurship.

In addition to the creative realm, 3D printing has tremendous potential for advancing scientific research and medicine. Researchers and scientists can utilize 3D printing to create complex models of organs, allowing for better understanding and study of diseases. Furthermore, the technology is already being used to produce prosthetics and custom orthodontics, improving the quality of life for individuals with disabilities.

The impact of 3D printing extends beyond individual applications; it is also transforming the entire manufacturing industry. With traditional manufacturing methods, production often relies on economies of scale to achieve cost efficiency. However, 3D printing enables companies to produce items on demand, reducing the need for large-scale production and minimizing inventory costs. This shift in manufacturing paradigm offers significant flexibility and agility for businesses.

Furthermore, 3D printing allows for more sustainable manufacturing practices. Traditional processes often result in significant material waste as items are machined or molded from larger pieces. In contrast, 3D printing only uses the exact amount of material required for the final product, reducing waste and minimizing the environmental impact.

As with any emerging technology, there are still challenges that need to be addressed. The cost of 3D printers and materials can be a barrier for individuals and small businesses. Additionally, the quality and durability of 3D-printed objects may not always match those produced through traditional manufacturing methods. However, as the technology continues to advance, these limitations are being addressed, making 3D printing more accessible and reliable.

In conclusion, 3D printing is transforming both manufacturing and personal creativity in unprecedented ways. With its ability to produce customized and complex designs, 3D printers are revolutionizing industries and empowering individuals. From healthcare to product development, the possibilities of 3D printing are endless. As the technology becomes more accessible and affordable, we can expect even more remarkable innovations to emerge, further solidifying its role as a game-changer in the world of manufacturing and personal expression.